Page 115 - 上海日成品牌 RCCN 线槽 电缆接头 尼龙扎带 尼龙软管 接线端子

P. 115

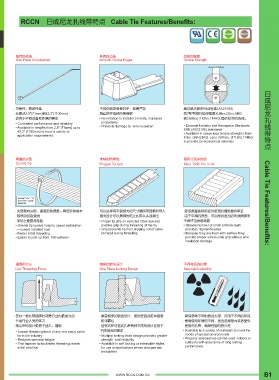

Cable Tie Features/Benefits:

• No irritation to installer’s hands, increases

• Consistent performance and reliability productivity • Exceeds Industry and Aerospace Standards

• Available in lengths from 2.8" (71mm) up to • Prevents damage to wire insulation SAE (AS23190) standards

43.3" (1100mm) to meet a variety of • Available in seven loop tensile strengths from

application requirements 8 lbs. (36N).8KG up to 250 lbs. (1112N).114KG

to provide an economical selection

• Finger tip grip on selected sizes assures Cable Tie Features/Benefits:

• Orients tip toward head to speed installation positive grip during threading of the tie • Greater number of small uniform teeth

— lowers installed cost • Grip prevents tip from slipping out of cable provides tighter bundles

• Faster initial threading tie head during threading • Because they are flush with surface they

• Easier to pick up from flat surfaces provide proper wire bundle grip without wire

insulation damage

• Lowest threading force of any one piece cable • Available in a variety of materials to meet the

tie in the industry • Multiple locking tooth design provides greater needs of special environments

• Reduces operator fatigue strength and reliability • Properly selected ties can be used indoors or

• Thin tapered tip facilitates threading, easier • Available in self locking or releasable styles outdoors with assurance of long lasting

initial insertion for use in applications where changes are performance

anticipated

• No irritation to installer’s hands, increases

• Consistent performance and reliability productivity • Exceeds Industry and Aerospace Standards

• Available in lengths from 2.8" (71mm) up to • Prevents damage to wire insulation SAE (AS23190) standards

43.3" (1100mm) to meet a variety of • Available in seven loop tensile strengths from

application requirements 8 lbs. (36N).8KG up to 250 lbs. (1112N).114KG

to provide an economical selection

• Finger tip grip on selected sizes assures Cable Tie Features/Benefits:

• Orients tip toward head to speed installation positive grip during threading of the tie • Greater number of small uniform teeth

— lowers installed cost • Grip prevents tip from slipping out of cable provides tighter bundles

• Faster initial threading tie head during threading • Because they are flush with surface they

• Easier to pick up from flat surfaces provide proper wire bundle grip without wire

insulation damage

• Lowest threading force of any one piece cable • Available in a variety of materials to meet the

tie in the industry • Multiple locking tooth design provides greater needs of special environments

• Reduces operator fatigue strength and reliability • Properly selected ties can be used indoors or

• Thin tapered tip facilitates threading, easier • Available in self locking or releasable styles outdoors with assurance of long lasting

initial insertion for use in applications where changes are performance

anticipated